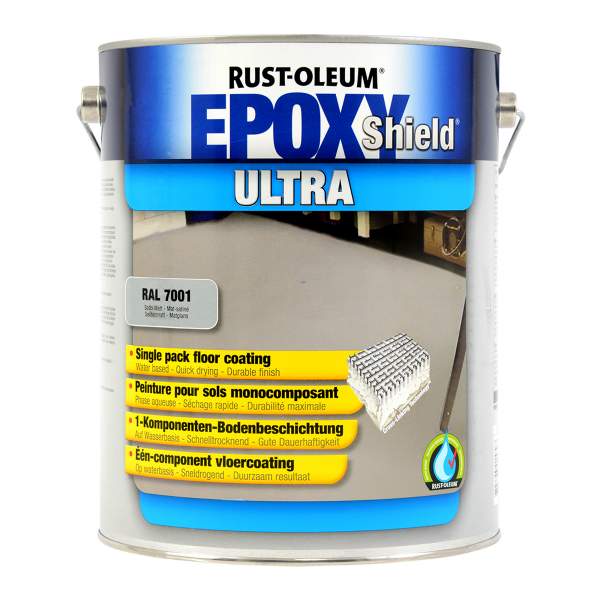

5200 Epoxyshield Ultra RAL7001 (Ready Mixed) 5L

In detail

Rust-Oleum 5200 Epoxyshield Ultra is quick-drying single pack water-based floor coating (epoxy-modified acrylic) for light to medium duty (normal foot traffic/limited vehicular traffic).

- Size

- 5L

- Application Methods

- Brush, Roller

- Coverage

- Up to 10sq/m per litre

- VOC level

- Medium

- Thinning

- Not required

- Touch dry

- 1-4 hours

- Recoatable

- 4-8 hours

- Suitable for...

- Interior use

- Scrubbability

- Washable

- Colour

- RAL7001

- Colour type

- Ready Mixed

- Finish

- Eggshell

- Cleanup

- Water & Detergent

- Base

- Water-Based

Available colours

Rustoleum 5200 Epoxyshield Ultra RAL7001 (Ready Mixed) is available in 1 colours from the Rustoleum Colour Cards.

Browse colours

Always ask your client to try their colour choice on the wall first. Colour cards and emulsion sample pots are available at your local Brewers or at designerpaint.com

Data sheets

Additional information

EpoxyShield® ULTRA (5200-series)

Quick-drying single pack water-based floor coating (epoxy-modified acrylic) for light to medium duty (normal foot traffic/limited vehicular traffic). Good resistance to diesel, motor oil, coolant fluid, various household chemicals and most types of tyre.

Surface preparation

Only apply to completely clean and dry concrete floors. Do not apply to smooth and completely sealed concrete or concrete containing a curing compound. Remove oil, grease and all other contaminants with EpoxyShield Cleaner/Degreaser 2901. Allow new concrete to set for at least 30 days. Remove laitance, loose and damaged concrete by sandblasting or keying with RUST-OLEUM Surfa-Etch 108. Repair all holes and cracks with EpoxyShield concrete repair products.

Always pre-treat absorbent, porous surfaces with EpoxyShield Sealer 5220. Roughen well-sealed and smooth concrete and treat with Epoxyshield Sealer 5220. Roughen still-intact floor coatings to ensure good adherence. Remove poorly-adhering old coatings with wire brush and sandpaper. During application the surface must be clean and dry.

Application

- Apply undiluted in at least two coats using a nylon roller or a polyester brush.

- For the best results use EpoxyShield Sealer 5220 as first coat.

- Recommended film thickness: 40 pm dry, (100 pm wet). The temperature of the surface must be at least 3°C above the dew point.

Related products

-

Surfa Etch 108.5 5L

BN487015F

Rustoleum

Next day delivery£84.18 inc.

VAT -

Epoxyshield Anti-Slip Additive 0.7KG

BN4944005

Rustoleum

Next day delivery£12.61 inc.

VAT -

Revolution Frame 9" x 1.75"

JT095007

Purdy

Store stocked line

Next day delivery£16.88 inc.

VAT -

Pro-Extra White Dove Semi Rough Sleeve 9" x 1.75"

JT09501307

Purdy

Next day delivery£9.19 inc.

VAT